|

product details

|

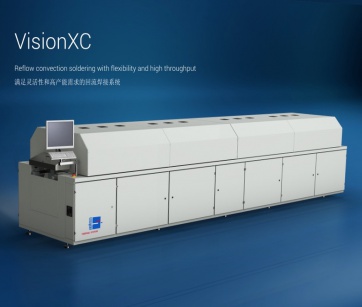

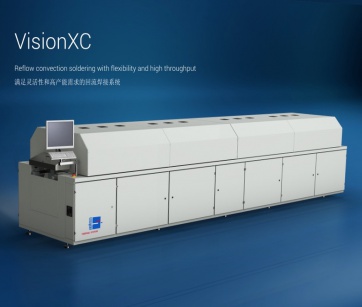

An ideal compact system

Small batch? Small production scale? For all electronic manufacturers, it is important to ensure high-quality production of components. This means that the reproducible welding results can be obtained with the best process performance, so that it can be maintained for a long time and can be invoked at any time. VisionXC is a product designed for this type of customer. It is compact in design and contains all the important technical characteristics in the smallest possible space. VisionXC is an ideal equipment for small and medium scale production lines, laboratories or demonstration production lines.

High quality and stable process

All heating areas of VisionXC can be individually adjusted and provide heat transfer and flexible temperature curves for each other and provide stable reflux process. The unique design of the hole nozzle array enables the process gas in the heating zone to be uniformly heated, thus ensuring the uniform temperature of the material. VisionXC uses multiple heating zones to significantly enhance heat transfer effect. The short distance between the nozzle array and the transmission belt and the airflow speed which can be adjusted separately on the upper and lower heating zones can make the components as evenly heated as possible. Minimize stress and consequent weld defects.

Safe transport in the furnace: flexible transmission system

The components are transferred to each area of the equipment during the welding process: from the preheating zone through the main heating zone to the cooling zone. For continuous process, transmission security is particularly important. Our equipment provides a highly flexible transmission system for this purpose.

Regardless of the size, length and thickness of the components, our transmission system can achieve the best match. The transmission track and speed are flexible and adjustable. VisionXP+ has also realized simultaneous parallel double track welding process (using lead or lead-free solder).

Reliable, clean and efficient residue management system

VisionXC excludes residues produced during welding by efficient filtration system. The 1-3 stage slag management system is integrated with the front end of the equipment. Each stage is composed of a cooling device and a filter. The fluid and crystal residue can be effectively removed. Reducing maintenance costs and improving production efficiency

High efficient cooling of components

VisionXC can be divided into 2~4 stage according to the type of production line. The cooling gradient can be accurately controlled through a number of independently adjustable fans in the control unit. At the same time, we also provide customized solutions for your products, laying the foundation for flexible production.

Convenient smart software: the simplest idea of operation

Our software solution can track all processes accurately. Visu2 includes process and product tracking tools, remote management tools and a comprehensive product library. It has intuitive user interface, significantly reducing the workload of software setup and operation training. You can browse all the documents by just a few clicks. Visu2 also provides multi-layer encryption management, which allows you to choose language, view data records and maintain reports.

The process and product tracking functions can be realized through bar code management and all related process parameters (with time marking).

|